The MARK data software was developed and refined through to commercial viability in amicable collaboration with well-known German and international manufacturers and operators of rail vehicles. Procedures and verification processes were subject to strict compliance with the international recommendation UIC V 660, the DIN 27201 standard and therefore the acceptance of the EBA.

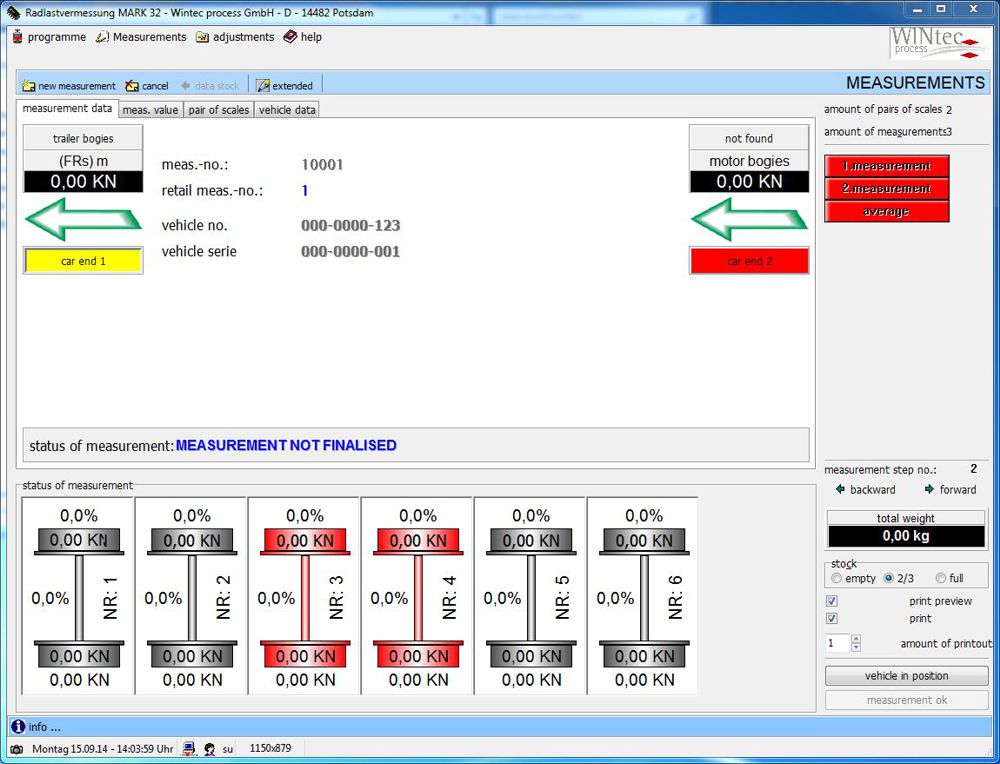

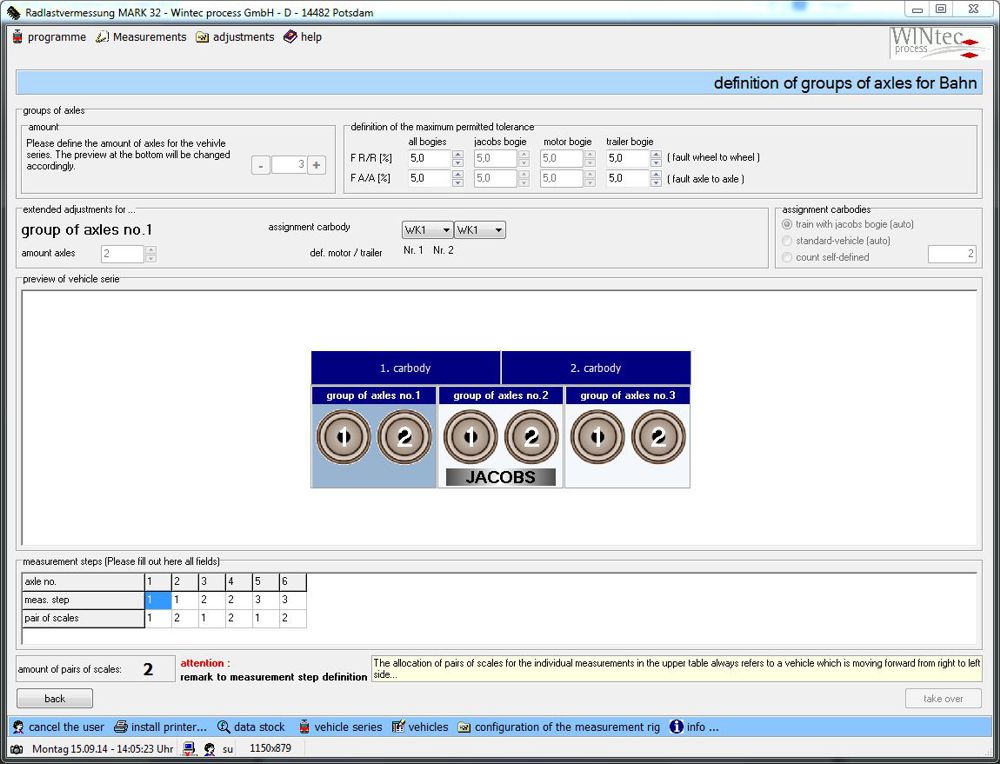

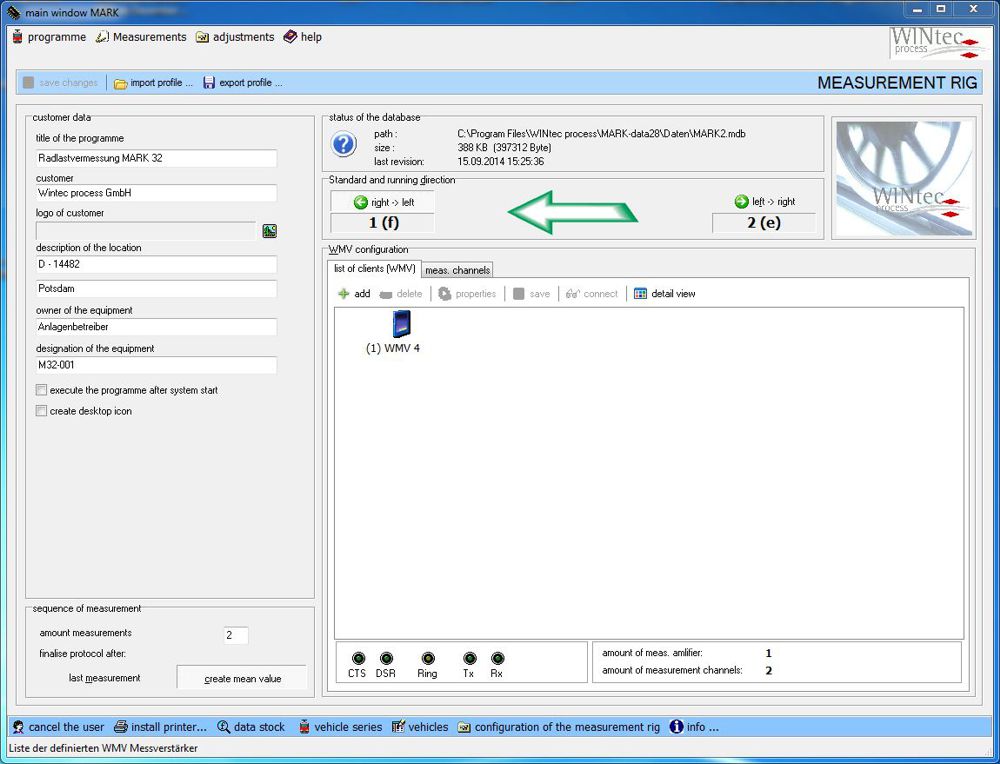

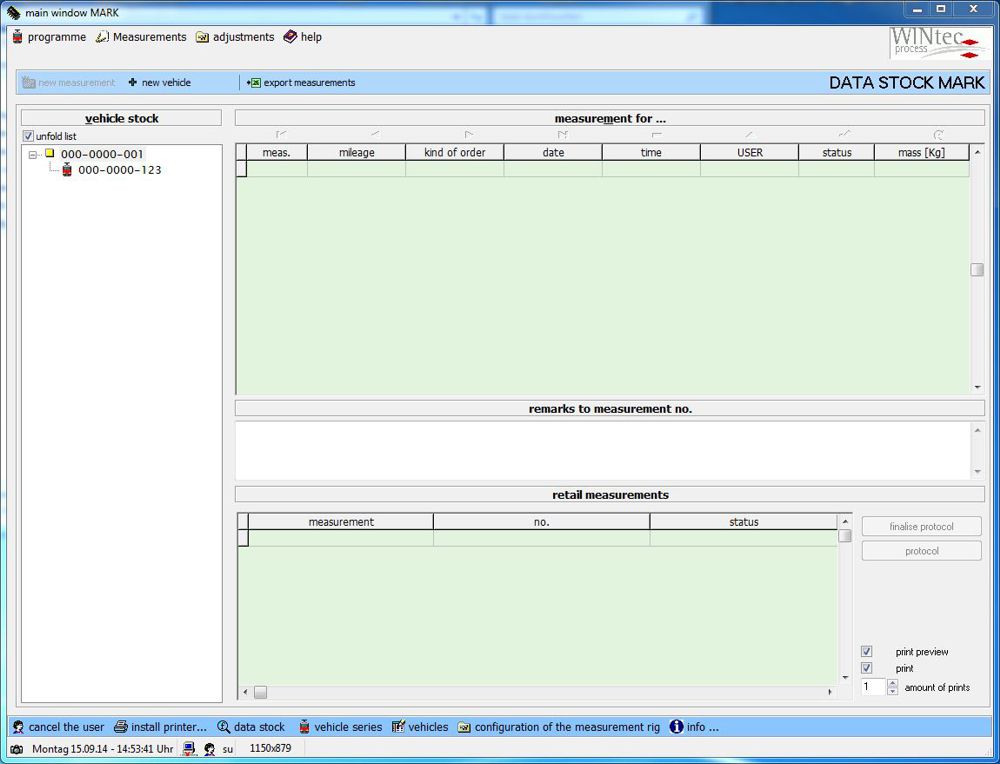

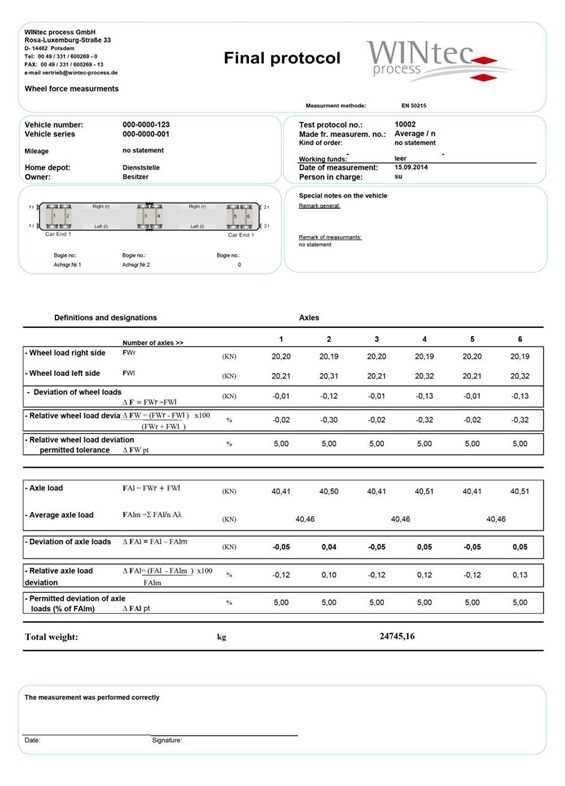

The standard version of the database software MARK data is capable of gathering data from up to 32 wheels at the same time and displaying the wheel contact force measurements. This means that it is possible to measure vehicles with up to 16 axles in one single step. A software upgrade can be carried out at any time.

MARK data features

MARK data features